Next-generation electric actuators that support CAN bus (control area network) communication are extending newfound intelligent controllability to linear motion applications, including those that previously used traditional electric actuators, hydraulic cylinders or manual operations. The benefits have been realized in higher efficiency, lower lifecycle costs and safer, cleaner operations.

Based on ISO standard 11898 for serial data communication, the control area network (CAN) was initially developed to reduce the cost and complexity of copper wiring in automotive applications with a simplified electronic bus architecture. To enable designers to take full advantage of this architecture, the Society of Automotive Engineers (SAE) developed the J1939 programming language and advanced it around the needs of automotive, agriculture, construction and other MOH applications.

While J1939 was ushering an age of intelligent automation in the automotive industry, manufacturing industries were seeking ways to leverage the bus architecture for motion control. Industrial applications, however, required higher transmission rates, more bandwidth and ways to integrate motion control with other applications. Such needs spurred the development of the CANopen® language, which uses an open standard platform that enables plug-and-play integration with other standard devices. This provides a smart architecture capable of integrating intelligent motion into other, higher-level automation schemes.

A look at the CAN bus architecture

CAN bus is a high-level communications protocol that provides a standard messaging structure for communications among network nodes under the control of an electronic control unit (ECU). Every message on an actuator module represents a node that has a standard identifier indicating message priority, data and control source. This enables plug-and-play interchanges of supporting devices that share the same network and comply with the messaging structure.

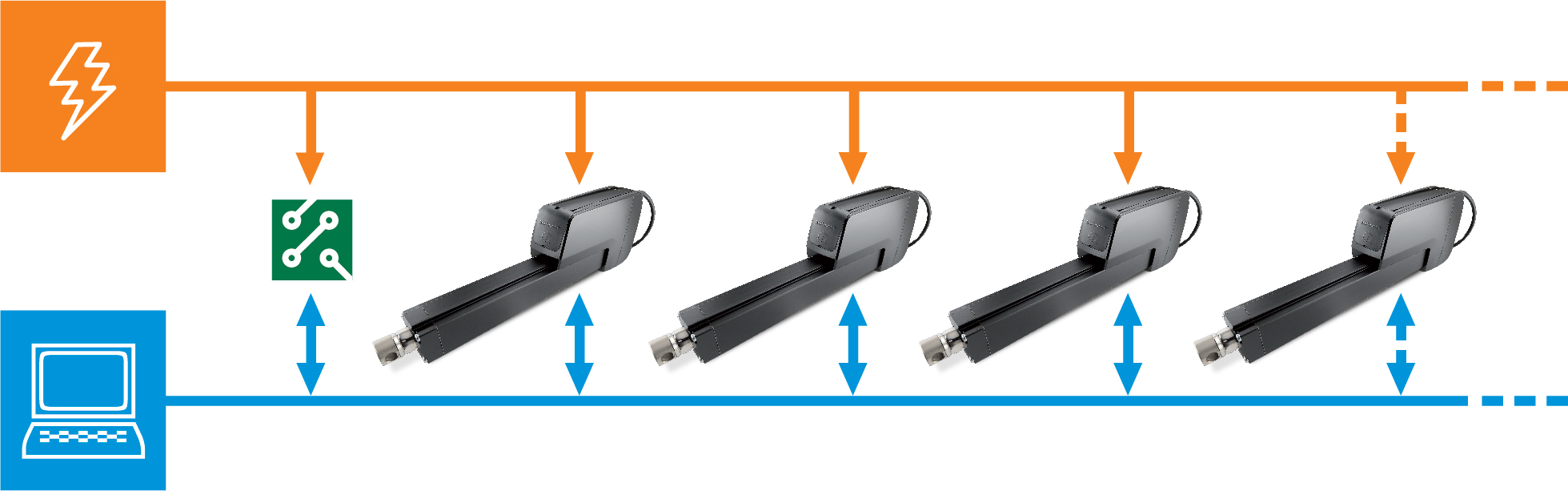

Figure 1 shows a typical CAN bus network. It illustrates four actuators with built-in CAN bus-compliant intelligence. Each actuator has two wires ? one that connects to an external power source and the other that communicates with the control source. The green box represents sensors or other components that could also be wired to the power source and the communications network without external relays. The orange line represents the two-wire bus that transmits the low voltage of power needed for the system, and the blue line represents the two wires that are used for information exchange. This represents a dramatic improvement over conventional vehicle networks in at least the following ways:

- Power is distributed across common wiring, eliminating the need for separate wiring between each device and the power source.

- Switching is embedded in the actuator electronics, eliminating the need for cumbersome external switching and connectors, etc. All commands are executed in the actuator.

- Information flows to an ECU from each device via the network bus, eliminating the need for independent connections between the devices and the ECU. ? Other equipment that might be integrated into the system connects with the network in the same way, eliminating the need for separate wiring, controls and additional configuration.

- A typical CAN network supports up to 256 nodes, including multiple actuators or other devices on each node ? something that would be all but impossible with a conventional network.

Figure 1. Typical CAN bus network, illustrating four actuators with built-in CAN bus-compliant intelligence.

The result is an efficient, compact solution that provides unprecedented monitoring and advanced control capability. Actuators are programmed to speak the same language as the ECU, allowing communication across a shared bus. This is dramatically different from conventional electronic architectures, which require a standalone ECU for each operation. This also enables more complex control strategies, such as deploying the same actuator in multiple applications.

Embedded position control

An actuator with embedded CAN bus can carry position control messages. A 14-bit signal informs the user of the actual actuator stroke position between 0.0 inches and a fully extended stroke, the accuracy of which depends on the stroke length and mechanical tolerances of a given model. Accuracy of the signal itself, for example, could be 0.004 inches/bit, which could contribute to overall system positional accuracy of +/- 0.02 inches or better depending on tolerances in the gearing, ball nut and screw assembly.

This is especially advantageous in comparison to hydraulic cylinder applications. Achieving that kind of positional information on a hydraulic system is expensive and hard to maintain. Instead of receiving a consistent electronic signal, monitoring the position of hydraulic cylinders requires measuring the amount of fluid that is being pumped through the lines and then using externally mounted encoders and limit switches to signal a control box when the desired points have been reached. This requires keeping fluid in motion throughout the system at all times, and when pumping stops, system creep affects the position and requires recalibration. It also renders hydraulic actuation much less effective for heavy duty applications requiring consistent, high-precision position control over longer periods. CAN bus systems, on the other hand, use encoders, limit switches and potentiometers to control position, and these are designed into the system electronics to enable absolute position determination.

A side benefit of absolute position control is that it enables consistent, reliable position memory. Because some machines might be deployed only during peak seasons such as Christmas or back-to-school times for distribution centers, and might sit idle for eight or nine months, it is sometimes useful to disconnect the battery to prevent it from draining. Without absolute position capability set at the factory, the user will have to recalibrate once they reconnect the battery.

Low-level power switching

Low-level power switching is standard with the CAN bus protocol, allowing operators to program the actuator to extend, retract or stop smoothly using low-level electronic signals rather than a higher-energy electrical current. This improves safety by reducing the hazard of electrical shock and simplifying design by allowing lower-rated control components. Soft start capability also allows the use of lower-rated power supplies and puts less stress on batteries and charging systems in machines.

Low-level power switching also enables controlling standard inrush to be up to three times the full load amperage for up to 150 milliseconds. This would enable direct programmable logic controller (PLC) connections, eliminating the need for expensive relays and the related installation costs. It also could include a sleep mode when the actuator is idle, which extends the battery by reducing energy consumption and battery drain.

Dynamic braking control is yet another benefit of low-level power switching. Once the power is cut to an actuator, it could take between 0.2 and 0.4 inches to coast to a full stop, depending on how the actuator is mounted. Electric actuators enable dynamic braking functionality, which can reduce that coast to about 0.2 inches by electrically forcing a short between motor leads inside the actuator. This improves repeatability and positioning capability.

Programming capability

Such advanced position control and switching enable programming of the drive to perform with an infinite number of movement profiles and custom motion strategies. For example, users can program the actuator to seek forward a few millimeters or make a small set of movements back and forth to hunt down the desired position. And because the system knows what it is supposed to do and monitors performance in real time, it can flag potential variances and trigger advanced algorithms to manage further alarms, corrections or shutdown.

With CAN bus, system developers have much greater flexibility to program the sensors and internal electronics to synchronize operations among multiple actuators. For example, they can program units to vary in speed depending on load or change speed to compensate if units speed up or slow down.

Electric actuators without CAN bus can provide absolute position readings, but they typically require significant power, heavier wiring, relays and other space-consuming and vulnerability prone wiring. CAN bus enables all of this to be embedded directly into the actuator and managed by embedded, low-level switching connected to the 2-wire CAN bus communications network and two power wires. This not only simplifies wiring in the machine but also brings all of those previous external electronics into the product – and warranty – of the actuator vendor.

Diagnostics and maintenance

In addition to returning real-time position data to the user, CAN bus-enabled actuators are constantly returning results of ongoing monitoring of temperature, current, speed, voltage and other variables, which enables advanced diagnostics and error handling. Feedback can arrive as quickly as ten times per second as the actuator constantly tests itself. If it detects a problem, such as surpassing a temperature threshold, the actuator finishes its programmed move – either fully retracted or extended – stops and sends an error flag to the computer ? all in fraction of a second. Following are some of the variables that can now be monitored with unprecedented efficiency:

Current. Current monitoring is a critical safety feature that shuts down the actuator on overload and eliminates the need for the traditional noisy mechanical clutch.

Voltage. Continuous monitoring of voltage protects the actuator by preventing motion if it detects it operating in an environment outside of the acceptable range.

Temperature. Internal temperature is monitored and, if it is outside the acceptable range, the actuator is shut down after extending or retracting stroke. Built-in temperature compensation allows the actuator to push the rated load at lower temperatures without nuisance tripping.

Load. Trip points can be calibrated at assembly to assure repeatable overload trip points independent of component and assembly variations. This not only assures repeatable performance but also relieves the user of having to recalibrate in the field.

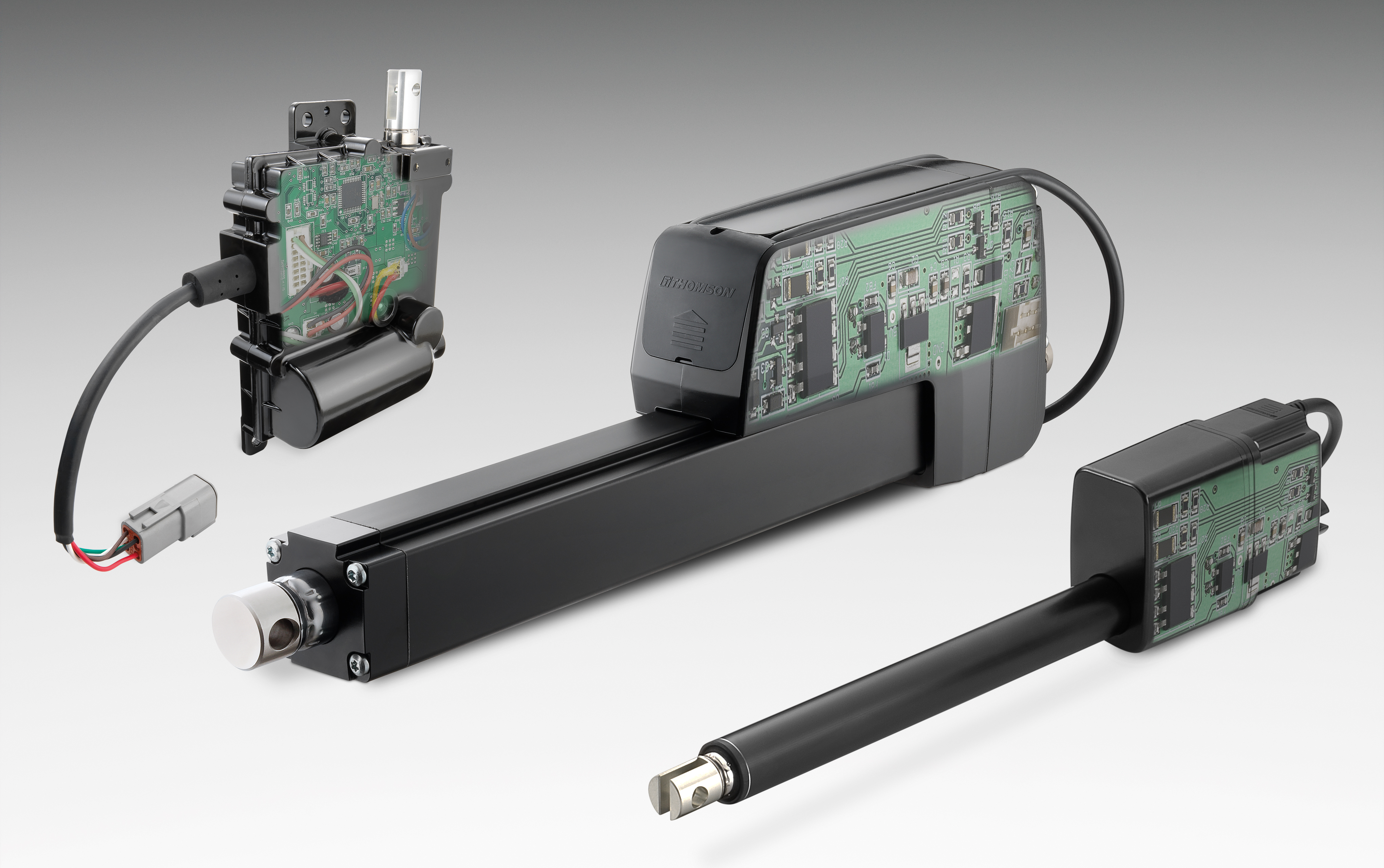

All such functionality can now be embedded within the actuator, available instantly and, via the network, potentially sharable for assistance with external troubleshooting. Thomson smart electric actuators, for example, are a plug-and-play solution, easily swapped out in case of a problem. (Figure 2) On the other hand, replacing a problematic hydraulic cylinder could involve a service call from the manufacturer and hours or even days of disassembly, reassembly, system bleeding and testing-- time that would be better spent in production.

Moreover, system health monitoring can occur remotely. For example, an OEM support technician in Iowa can log in to a combine in North Dakota to diagnose a failed actuator by analyzing electronic message flags on temperature, position, current and input voltage.

Figure 2. Thomson smart electric linear actuators feature simplified control architectures embedded directly into their electronics. This enhancement allows for a number of functional and control benefits.

Enriching the dialogue

In many ways, optimizing the performance of an actuator is a function of the dialogue quality between the users and the device. With a CAN bus-compatible language combined with advanced embedded electronics, users have more flexibility in telling their actuator where and how fast they want it to move, and when they want it to stop, and they will get instant feedback as to whether it has behaved accordingly.

You can engage in this kind of dialogue with a non-CAN bus electric actuator, but it requires more external switches and wiring. You can also engage with a hydraulic cylinder, but it is a far longer and much more complicated conversation. By utilizing a common, highly efficient language, the CAN bus standard moves the discussion from how the communications will be managed to what exactly the user wants to accomplish.

Whether you are using J1939 programming in automotive MOH industries or CANopen in industrial automation, the result can be greater control and design flexibility, faster engineering, more efficient installation, and overall lower cost of ownership.