Balancing large or awkward loads can be a challenge for many industrial applications. Whether it is the hood of a construction vehicle, a large work platform, a solar panel or an industrial material handling system, movements that are imbalanced can impact performance, cause unnecessary wear and tear, and jeopardise worker safety. Synchronizing actuators has traditionally required complex integration of external devices and extensive configuration or programming, but the latest generation of smart linear actuators with onboard electronics is easy to install and capable of synchronizing automatically.

Why synchronize actuator operation?

A load that is heavier on one end could lead to potential damage to equipment or its components if not handled properly. While some imbalance is predictable, others are the result of unanticipated events such as sudden load shifts. Equipment designers account for imbalance by using multiple actuators, but unless all are synchronized closely, problems can emerge. Using a pair of actuators to assist in raising and lowering the hood of a large construction vehicle, for example, can result in bouncing, slow operation, or unnecessary wear and tear if the actuators are not operating in tandem.

The larger and more uneven the load, the greater the need to synchronize the actuators that move it. Stabilising up-and-down and side-to-side motion of a 20-meter platform supporting workers as they build a jumbo jet, for example, could require synchronizing more than 10 actuators. Complicating the challenge is the potential for the load to vary considerably during operation as workers move around the platform, and the fact that the platform itself may not be uniform due to weld tolerances in joined segments.

Each Thomson Electrak® HD smart electromechanical actuator can push or pull up to its maximum dynamic load capacity to automatically synchronize an uneven load.

When properly synchronized, multiple actuators can also work together to handle loads larger than any of them could handle individually. The likely effectiveness in synchronizing large or awkward loads varies considerably depending on whether they are using hydraulic, electromechanical or smart electromechanical actuators with intrinsic synchronization.

Synchronizing hydraulic actuators

In the simplest applications involving hydraulic actuators, designers might deploy two units to balance a wider load such as the hood lift mentioned earlier. This would involve running fluid lines to each actuator and provide some degree of synchronization, but the actuators would not be operating with sensitivity to each other’s position. There would be no easy way to compensate for significant load changes or wear and tear that may increase over time.

When comparing a hydraulic cylinder versus an electromechanical solution, one might consider intuitively the hydraulic cylinder to be a more cost-effective solution, but when considering all of the components that go into a hydraulic system (pump, reservoir, manifold, hoses, control, etc.), the electromechanical solution provides a significant reduction in overall material and installation cost. On top of that, an electromechanical system requires no maintenance and will provide a cleaner environment as compared to a hydraulic system, which has numerous leakage points for fluid, adding even more cost over its operational lifecycle.

Synchronizing electric actuators

During the 1960s and 1970s, motion designers began to replace hydraulic actuators with electric actuators. These were cleaner and easier to synchronize than hydraulic actuators but still required attention. System designers would need to program external controllers or switches to read digital position from encoders. Based on that, the program would adjust the speed of each actuator as needed to balance the load.

Synchronizing smart actuators

Embedding microcontrollers into electromechanical actuators has added significant synchronization capabilities. Manufacturers embed logic control and switching directly into the actuator itself. They operate with only four wires, two of which supply power, while the other two enable exchange of data across a communications network, eliminating the need for an external controller. Because all actuators are on a common circuit, they can read each other’s speed and position and adjust accordingly – but they still require someone to program the feedback loop that tells them what to do and when.

The latest generation of smart actuators, however, are even smarter. Manufacturers such as Thomson Industries, Inc., now embed all of the tracking capabilities and synchronizing logic within the actuator itself, making virtually any number of equipped actuators self-synchronizing.

Applications using automation can benefit from internal condition monitoring with every smart electromechanical actuator. This keeps the actuators running within rated specification and shuts them down if temperatures rise, loads are exceeded or input voltage is insufficient.

In a typical configuration, a user would simply connect one actuator in the system to the switching device (i.e. simple switch or PLC) via two low-current wires. Any actuator in the system can be selected. When powered, all actuators in the system will continuously communicate position and speed, regardless of load fluctuation. When the system detects any variation of position, a message is sent to each individual actuator to either speed up or slow down until equilibrium is reached. Adjusting in step is necessary in that it enables the system to compensate for inconsistencies in load or mounting.

Applications

Actuator synchronization is valuable in large-load, heavy duty applications with potential for imbalanced operation. This new technology enables users to synchronize actuators each capable of handling up to 16 kN loads and with stroke lengths of up 1 meter (up to 10kN). There is also virtually no limit to the number of actuators that can be synchronized. In addition to the hood lifts and work platforms already mentioned, actuator synchronization can be valuable in the following applications:

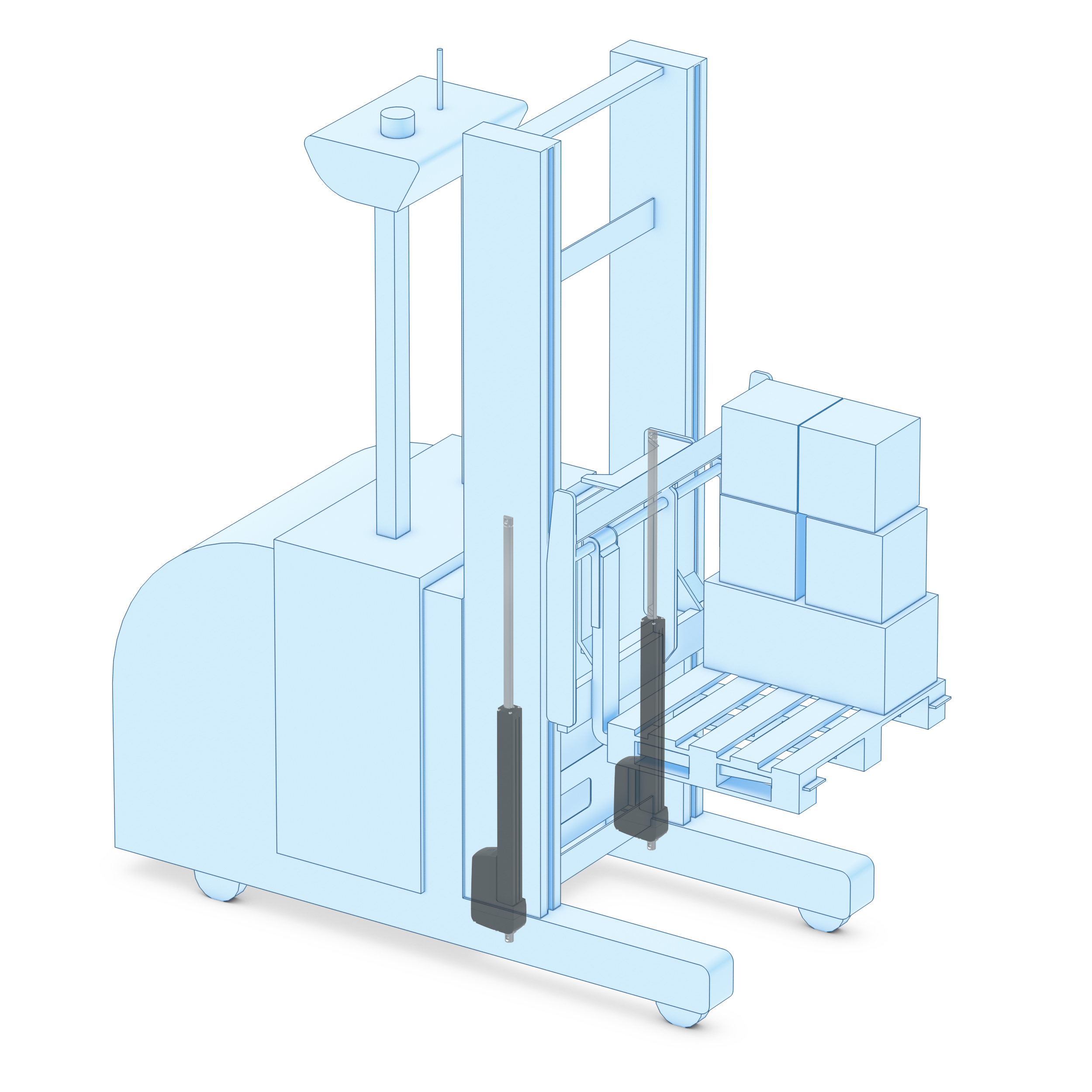

- Automatic Guided Vehicles (AGVs), where synchronization can enable handling of a broader range of materials without human intervention.

- Solar panels, where synchronization can enable more robust operation of large panels as they track the sun’s position, minimising impact of wind shear and reducing the need for specialised supports

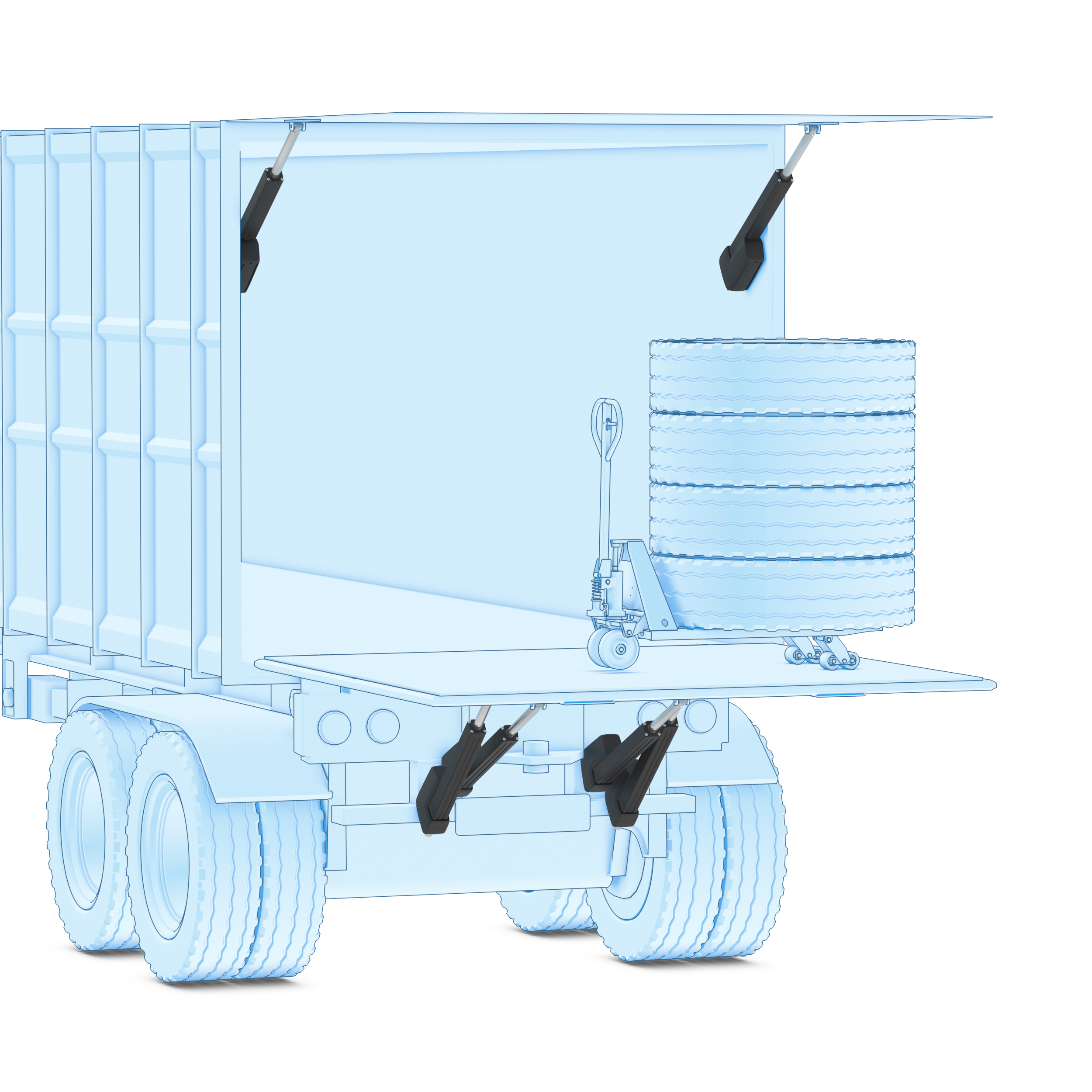

- Mobile lifting platforms, where synchronization can improve handling of lift gates without the complexity and maintenance requirements of a traditional hydraulic solution.

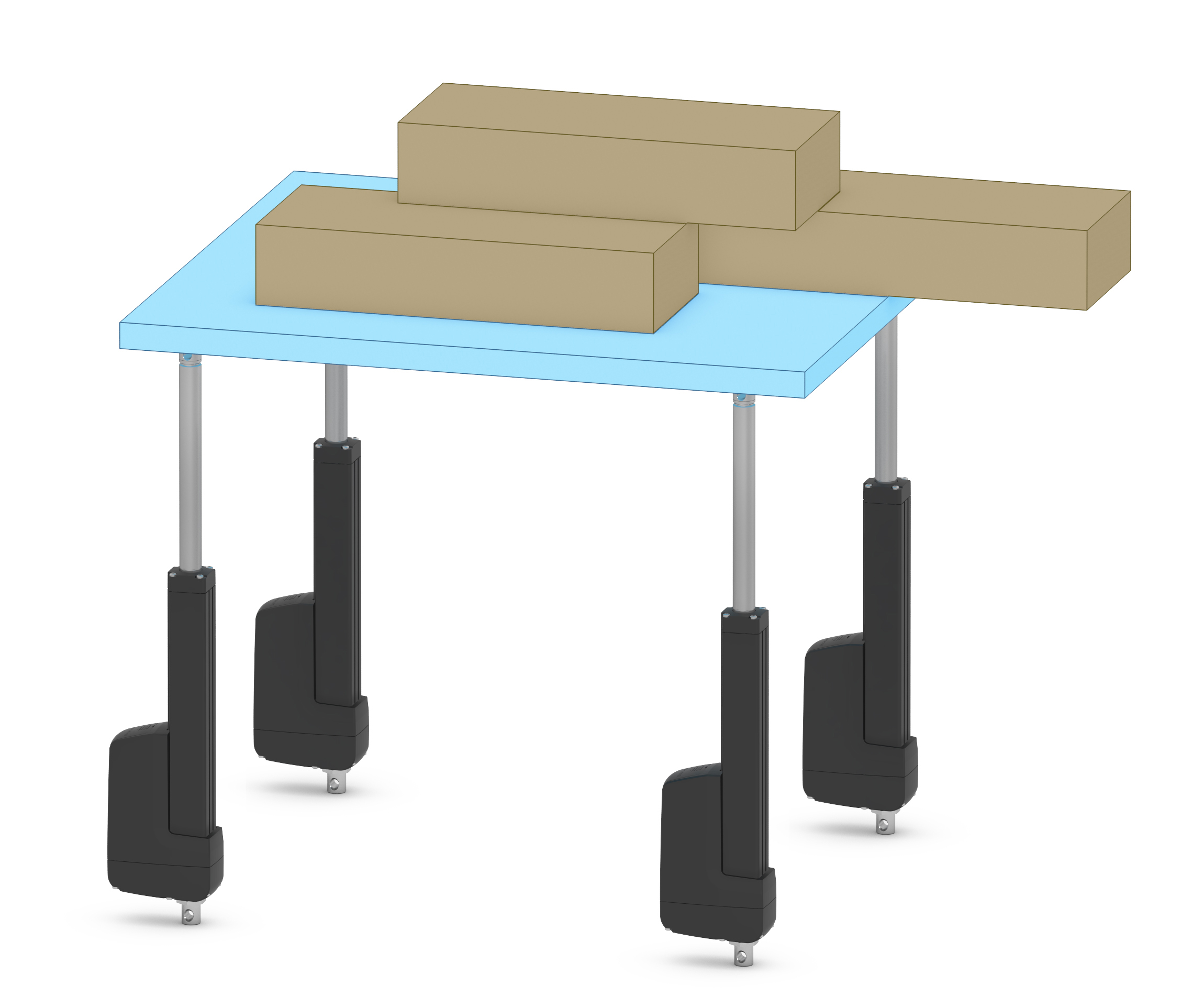

- Assembly stations, where synchronization can contribute to effective and ergonomic lift support for off-center or awkward loads.

- Industrial logistics trains, where synchronization can automatically correct imbalances between the front and backend loads.

- Doors on ovens and large processing equipment, where synchronization can enable smoother, safer opening and closing.

- Ergonomic patient-handling equipment, where synchronization can improve the quality of patient care by synchronizing operation of equipment such as lift tables and lift columns.

- Marine applications, where synchronization can lead to smoother, more responsive steering through improved operation of rudder assemblies.

- Structural engineering, where synchronization can improve operation of automatic loading doors in factories and warehouses, and floodwater damage-prevention gates.

Utilising synchronization for mobile lifting platforms on vehicles provides a robust, reliable solution without the complexity and maintenance requirements of a traditional hydraulic solution.

Actuator synchronization optimised

The ability of multiple actuators to synchronize themselves moves the handling of large and awkward loads to a new level of capability. It results in improved and more reliable performance, and faster and safer operation as it provides more efficient and longer life of the actuators themselves. Moreover, if the need for synchronization is recognized up front, installing self-synchronizing actuators carries a low-cost installation, faster setup and minimal long-term maintenance requirements. As more industrial operations become digitised and connected, the need to synchronize operation of multiple actuators – and the related benefits of doing so – is likely to grow.